It’s opening day at Wal-Mart’s new Providence store, and Steven P. Hamburg, Brown’s Ittleson Associate Professor of Environmental Studies, has his head inside a frozen-food case. He’s examining the strips of LED lights that illuminate the chicken tenders. When his head emerges he is grinning. “These aren’t mine, but that’s a cutting-edge technology,” he raves.

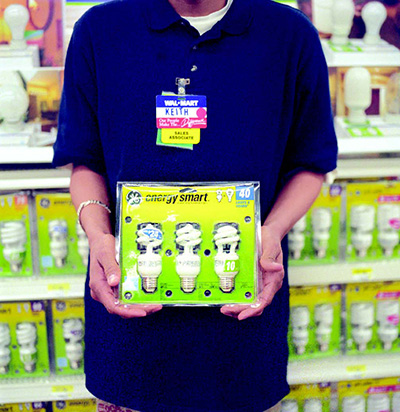

Steve Hamburg is not a Wal-Mart shopper. Until recently he had no idea where to find the nearest store. But since meeting Wal-Mart’s CEO in the fall of 2005, Hamburg has been on a mission to use the superstore’s immense marketing and retail punch to promote one of his chief obsessions: compact fluorescent light bulbs. Today Hamburg navigates the new Providence store with the familiarity of a veteran bargain shopper, except that instead of counting pennies he’s counting skylights—too few to help with lighting and heating costs, he muses—and calculating the energy consumption of the ceiling lights. He stops at the end of the light-bulb aisle. “Now this is mine,” he says proudly.

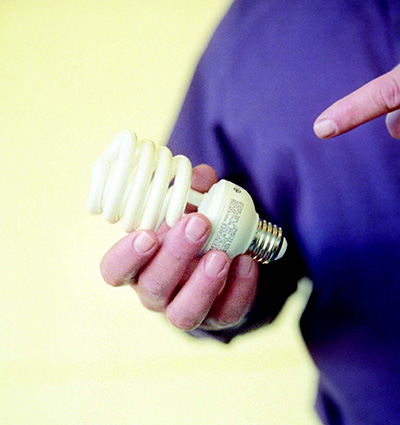

Occupying four feet of prime retail real estate known in the business as an “end cap” is a brightly colored educational display designed to teach Wal-Mart shoppers how to conserve energy and cut their electric bills with compact fluorescent bulbs. The gist of the message is that although the bulbs may cost eight times more upfront than conventional incandescent bulbs, they last up to ten times longer and consume 75 percent less electricity. The trick, Hamburg says, is to get Wal-Mart shoppers to buy and use them. The goal may seem quixotic and idealistic, but to Hamburg it’s a mission.

Hamburg’s display shows the ten most popular incandescent bulbs—including standard bulbs for lamps, interior and exterior floodlights, spotlights, ceiling-fan bulbs, and white globes for bathroom fixtures—and matches each model with its compact fluorescent, or CFL, counterpart. Around the corner, an entire aisle is given over to light bulbs and related products. Yards and yards of the most valuable shelf space—the area between a shopper’s eyes and knees—are packed with CFLs. There are “soft light” versions that cast a yellowish light, and “daylight”-colored bulbs with a colder, bluer cast. There are swirl-shaped bulbs whose tiny fluorescent tubes are twisted into a form that resembles a soft-serve ice cream cone, and there are classical-looking bulbs in which the swirl is encased in a globe shaped like the incandescent model it replaces. With this wonderland of energy-efficient bulbs to choose from, a customer has to bend down to find an old-fashioned incandescent.

Which a woman does while Hamburg is standing there talking.

Excusing himself, he walks over and politely asks the shopper if she knows that the swirl-shaped CFLs in front of her (six for $9.88) last many years longer than the incandescent bulbs she’s holding in her hand (four for a dollar). Does she know that each CFL will cut her electric bill so much that not only will she recoup the extra cost, she’ll save nearly forty dollars over the life of the bulb?

“Would you consider buying these, knowing they’ll actually save you money?” he asks, pointing toward the CFLs.

“I’ll think about that,” she says firmly, “when I have more money in my pocket.” She leaves with the incandescents.

“That’s the conversation I had with Lee Scott,” Hamburg says with a shrug.

H. Lee Scott Jr. is Wal-Mart’s CEO. Hamburg first met him over dinner at New Hampshire’s Mount Washington Observatory—elevation 6,288 feet—in the fall of 2005. At the time, Wal-Mart had begun trying to woo middle class shoppers and burnish its battered public image by establishing itself as an environmental leader, and a consultant had arranged for Scott and Wal-Mart’s vice president for strategy and sustainability to meet with a group of environmentalists and scientists, among them Hamburg. Scott spent the night at the observatory, which collects weather data twenty-four hours a day, and Hamburg, who runs a forest research project in New Hampshire, arranged for him to visit a maple-syrup farmer so the CEO could see firsthand how climate change was causing oaks to begin crowding out the sugar maples that are the source of maple syrup.

As luck would have it, the visit was scheduled for the first day of classes at Brown, so after teaching Hamburg drove four and a half hours north to join the group on Mount Washington. The New York Times reported that the businessmen and environmentalists talked climate change over turkey and mashed potatoes. (Hamburg disputes this. “It was some kind of red meat,” he recalls. “I remember because I don’t eat much red meat.”) At one point during a discussion, Scott asked Hamburg how Wal-Mart could minimize its stores’ environmental impact. Hamburg replied that the company’s real power to promote environmental responsibility lay not in its energy infrastructure but on its shelves. “Take compact fluorescent bulbs,” Hamburg remembers telling Scott. “Here’s a product you can really make progress on. It’s a win-win.”

As Scott would later announce in a speech broadcast to Wal-Mart employees worldwide, “a light bulb came on for me … and that’s a compact fluorescent light bulb!” Last fall, Wal-Mart announced its intention to sell 100 million compact fluorescents a year by 2008—one for each customer.

If the company meets its goal, Hamburg says, “By 2011, Wal-Mart customers will be emitting 100 million metric tons less carbon dioxide a year, eliminating the need for seven average-sized power plants.” That’s comparable to the total annual electrical consumption of all the houses in Rhode Island, New Hampshire, Maine, Connecticut, and Vermont. What’s more, Hamburg adds, the spillover effect as other retailers join the drive “could be double or triple that number.” (Competitors like Lowe’s and Home Depot are already marketing compact fluorescents heavily. Lowe’s currently offers rebates on its Web site. And Web sites to promote and track the sales of compact fluorescents include onebillionbulbs.com and the Yahoo-based 18seconds.org.)

Is extinction threatening the incandescent light bulb? It is certainly under attack at an unprecedented scale. Legislation to ban incandescent bulbs has been proposed in California, and the European nations are actively discussing plans for a phase out. In February, Australia announced it would phase out the bulbs completely over the next three years, thereby becoming the first nation to ban incandescent lights. The Australian government estimates that by 2015 the ban will reduce the country’s greenhouse gas emissions by 4 million tons a year.

Unfortunately for incandescent bulb manufacturers, most compact fluorescent bulbs are made in China, which is an important source of cheap labor. (Because the small glass tubes in compact fluorescents must be twisted by hand, making them is more labor-intensive than producing conventional bulbs.) The Dutch manufacturer Royal Philips plans to stop making incandescent bulbs altogether by 2016. General Electric, however, is fighting back; it announced in February that it plans to produce a new line of low-energy incandescents by 2010. Still, even Thomas Edison’s home state, New Jersey, is recommending that residents switch to compact fluorescents as part of its Clean Energy Program. The state distributed 1.2 million CFLs in 2005.

Incandescent bulbs have in fact evolved very little since Thomas Edison popularized them in the late nineteenth century. The technology is elegantly simple. An electrical current runs through a thin tungsten wire filament, producing heat. As the filament reaches a temperature between 2,200 and 2,500 degrees Celsius, it begins to glow, emitting light. The great design flaw of such a bulb is the inefficiency of using so much heat. About 90 percent of an incandescent bulb’s energy is lost as heat. Touch a hot light bulb and see for yourself.

In a fluorescent bulb electricity excites gas molecules (typically argon) in a glass tube. The interior of the tube is coated with a phosphorescent powder that glows when the excited gas molecules hit it. Heat loss is reduced (although it still accounts for the majority of the energy used). As a result, a compact fluorescent bulb needs only 13 watts of electricity to emit the same amount of light as a 60-watt incandescent bulb.

A second design flaw in a conventional bulb is that the tungsten filament must be very thin. When subjected to the high heat needed to make it glow, the wire filament degenerates and soon breaks down. Fluorescents last up to ten times as long, depending on their quality and use.

Although many businesses caught onto the potential savings early and outfitted offices with fluorescent light fixtures, getting people to use the lights has been challenging. That’s the challenge Wal-Mart seems determined to overcome.

Not long after the Mount Washington summit meeting, Hamburg received a serendipitous visit from Josh Apte ’04, a former student, who was in Providence while on vacation from his environmental research job at the Lawrence Berkeley National Laboratory in California. Hearing about the Wal-Mart project, Apte and one of Hamburg’s grad students, Adam Wienert ’06 AM, ran some quick calculations and concluded that Wal-Mart shoppers use nearly half a percent of all the energy used in the United States just to light their homes. Inspired by the potential, Hamburg signed on as a consultant to BluSkye, the consulting group that had first introduced him to Lee Scott, and hired Apte and Noam Ross ’06 to research how Wal-Mart could increase its sales of CFLs. Hamburg asked Wal-Mart for $20,000 to pay for travel expenses and his students’ salaries. (He estimates the company paid for about a week of his own time.)

One of his first suggestions was that Wal-Mart put energy-efficient bulbs in the ten ceiling fans on display in each store. “I told them the old lights are hot; they’re inefficient. Plus you’re not modeling what you’re preaching,” he says. The change is saving the company $8 million dollars a year.

In December 2005 Hamburg attended a meeting between Wal-Mart and General Electric executives at which the retail giant told its supplier that it would be heavily promoting CFLs. (“I represented civil society,” Hamburg says. “I presented goals not in terms of bulbs sold but in terms of sockets filled with CFLs. The GE folks weren’t ecstatic with me.”) According to articles in the New York Times and Fast Company, GE initially balked at Wal-Mart’s goal, but given its immense global purchasing power, Wal-Mart got its way. (It usually does.) Philips and Osram Sylvania came along, too.

Although Philips had first introduced compact fluorescent bulbs designed to fit in standard sockets way back in 1979, the CFLs had several flaws that consumers rejected so soundly the bulbs are still trying to recover. Those early CFLs were slow to light, and the light they did emit was dim and unpleasantly cold. They buzzed and flickered. They were too bulky to fit in many light fixtures. And they were expensive.

Thanks to the Energy Star program run by the U.S. Department of Energy and the U.S. Environmental Protection Agency (EPA), manufacturers gradually learned to make a better light bulb. Most of the new CFLs fire up instantly, fit in standard light fixtures, and give off strong, unwavering light. But the quality of the new compact fluorescent bulbs remains inconsistent. Hamburg hammered away at Wal-Mart’s buyers about the need to supply high, uniform quality lights. If a customer pays extra for a compact fluorescent, notes Apte, who is now earning a PhD in energy efficiency at UC Berkeley, it had better work or you’ve lost that customer. “Steve was never afraid to be a pain on these issues,” Apte says.

Another deterrant for consumers has been labeling. Customers couldn’t figure out what type of bulb they needed for a given purpose; nor were they able to compare one manufacturer’s product to another’s. At Hamburg’s urging, Wal-Mart strong-armed General Electric, Philips, and Osram Sylvania to adopt similar labeling criteria so customers could find the illumination they wanted. To help customers identify the bulbs they’re trying to replace and determine exactly which CFLs are the best match, Hamburg and his team helped Wal-Mart design the educational display that he points to with such pride at the end of each store’s light bulb aisle. Wal-Mart has also forced its suppliers to drop their price. Executives knew their shoppers could not afford three or four dollars a bulb. They pressured suppliers to bring down costs, and as a result the bulbs on its shelves now are priced as low as $1.65 each.

As part of its overall environmental push, Wal-Mart is also demanding that suppliers reduce packaging waste (and cut the cost of hauling it off). When Hamburg visited Providence’s new Wal-Mart this winter, the vast majority of the CFLs on the shelf were still in bulky plastic containers, but across the aisle he was happy to find six-packs of compact bulbs in segmented cardboard boxes. “I’ve pushed for these,” he said, pointing out that the ultimate goal is for consumers to replace the used bulbs in the cardboard containers and return them for recycling.

Recycling compact fluorescents (which is already mandatory in Europe) will mitigate another of their potential downsides. The bulbs contain small amounts of mercury—4.5 milligrams per bulb—which could pollute landfill sites when they’re disposed. Analysis by the EPA, however, demonstrates that the mercury in compact fluorescents is much less than that emitted by the coal-fired electrical plants required to power a comparable number of incandescent bulbs.

The quality of CFL-produced light remains an issue, however. Despite CFL manufacturers’ efforts to mimic the golden glow of incandescent light bulbs, the energy-efficient bulbs still cast a relatively cold light. Neither the “soft light” nor the “daylight” version really invites you to curl up with a book. And while manufacturers have managed to squeeze the little fluorescents into the shape of reflector bulbs like spotlights and floodlights, some applications remain just plain ugly. “We’ve got a way to go on that one,” Hamburg acknowledges as he checks out the blob-shaped fluorescent candelabra bulbs in his Wal-Mart display.

Light fixtures with dimmer switches also present a problem, even for compact fluorescents specified for that use. And small “can” lights designed for halogens are problematic, as well, since even the relatively small amount of heat generated by compact fluorescents builds up in the can and fries the electronics, Apte says.

Casually propped on a shelf in Hamburg’s office is an EPA award for explaining how human-created greenhouse gases contribute to climate change. This ability to explain science, says Annie Petsonk, an attorney at the Environmental Defense Fund (EDF), is Hamburg’s great strength. It’s why she recommended that he be included in the group that met with Wal-Mart’s Lee Scott.

“I don’t know anyone who can lead someone through a forest and explain acid rain the way Steve can,” she says. In 1997 Hamburg coauthored an EDF report called Seasons of Change: Global Warming and New England’s White Mountains. To illustrate the economic damage global warming might cause the region, the report pointed to factors threatening the fall foliage, the ski industry, trout fishing, timbering, and maple sugaring, all of which could suffer to varying degrees as summer droughts and shorter, warmer, winters hit northern New England. “The idea of capping greenhouse gases from power plants had its origins in that report,” Petsonk says.

As a popular teacher Hamburg says his goal is to teach his students tools they can transfer not only from the classroom to the real world, but from one kind of problem to another. Working on the Wal-Mart project, Noam Ross says he approached the store’s light bulb aisles as if they were an ecosystem. He tried, for example, to determine the life cycle of the products displayed there, calculating at what point CFL sales will naturally drop off as the market for them becomes saturated. (He estimates the tipping point as 100 million sales.) Ross compares the problem to studying an animal cohort from birth, through its growth cycle, and to its death, analyzing its impact on the environment during its natural life cycle. “The key to ecosystem analysis is that you have to ensure that you’re looking at everything,” he says. “That’s crucial whether you’re looking at an ecosystem or an economy.”

This type of systems analysis is one of the primary skills Hamburg teaches at Brown, where he holds appointments in the Center for Environmental Studies, the Department of Ecology and Evolutionary Biology, and the Watson Institute for International Studies (where he runs the global environment program). He is also an ardent proponent of interdisciplinary thought. To analyze the variables affecting a challenge like energy-efficient-bulb sales, he says, “students have to have knowledge, yes, but they don’t have to have the same kind of knowledge. I’m a forest ecologist, but whether it’s a forest or a rack of appliances, I can look at it the same way.”

Sitting on a bench in Wal-Mart, he points out a rack of calculators priced at a dollar apiece and sighs. “Here we are, sitting in the temple of retail gone wild. It’s not about quality; it’s all about quantity. You can’t make those for under a buck.”

Hamburg’s alliance with Wal-Mart has not been an entirely natural one, and he’s drifted away from it lately. “It’s not an easy fit,” he says. “The academic in me keeps asking questions when the managers want to move on.” Academia is not an entirely easy fit for Hamburg either. He poses himself a philosophical, perhaps rhetorical, question: “What is the social compact of an academic? Is it to create new knowledge or to make sure it gets used?”

Hamburg earned his master’s and doctorate in forest ecology at Yale. At Hubbard Brook Experimental Forest in New Hampshire and at another forest on Taiwan, he studies the impact of human activity on forests, as well as the effect of such natural disasters as typhoons and ice storms. He was lead author of the Intergovernmental Panel on Climate Change’s special report on land use, land-use change, and forestry, and is vice chair of the International Term Ecological Research Network, a grouping of ecological research sites in thirty-four countries.

As a scientist Hamburg recoils from the labels advocate and activist, both of which are considered obstacles to academic objectivity. But if you spend time with him, it’s clear that he is passionately committed to the public policy implications of his research. No venue is too small. He spent a Friday night this January addressing a local Unitarian Universalist congregation about climate change. He’s testified before the U.S. Senate and has advised both the late U.S. Senator John Chafee and his son, former U.S. Senator Lincoln Chafee ’75, on environmental issues.

After his first day of teaching this semester, Hamburg headed back to his office to help the man who defeated Lincoln Chafee last fall, U.S. Senator Sheldon Whitehouse, whose staff was visiting to collect briefing information for Whitehouse’s inaugural appearance before the Senate’s Committee on the Environment and Public Works. Hamburg and his colleagues had prepared maps showing the potential damage to Rhode Island’s Narragansett Bay from a twenty-foot rise in sea level or a Category Three hurricane with a five-foot storm surge. After a lengthy discussion of which images would work best, the Whitehouse staffers left, and Hamburg spent the rest of the afternoon meeting with undergraduate and graduate students. He offered to make a phone call on behalf of one student to expedite some research at the National Archives. He recommended potential mentors, fellowships, and funding sources. He prodded his students to work several tracks at once, to initiate contact with other scholars.

Get moving, he urged them; don’t wait for people to come to you.

Charlotte Bruce Harvey is the BAM’s managing editor.